What Is The Difference Between Batch Fryer and Continuous Fryer?

Jul 21, 2023 | Emily

125

125

125

125

Frying is a popular cooking technique used in numerous food industries to achieve crispy and flavorful products. Two primary types of fryer systems, batch fryers and continuous fryers, serve this purpose. Each method has its advantages and disadvantages, and understanding the differences between them is crucial for businesses to make informed decisions regarding their frying processes. In this article, we will delve into what is the difference between batch fryer and continuous fryer, exploring their mechanisms, applications, and advantages.

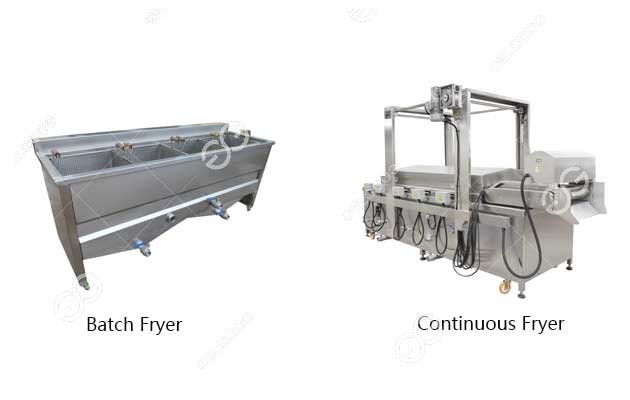

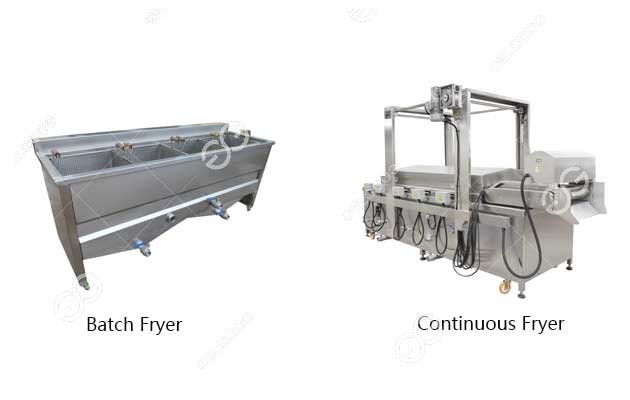

Batch Fryer

A batch fryer is a traditional frying system where food products are fried in specific batches. The process involves immersing the food items into hot oil until they reach the desired level of crispiness and color. After each batch is fried, the food is removed, and a new batch is added. This method is commonly used in smaller-scale operations, such as restaurants, food trucks, and some small to medium-sized food production facilities.

Advantages of Batch Fryer:

Versatility: Batch fryers can handle a wide variety of products, as different items can be fried in separate batches without flavor mixing.

Simplicity: The setup and operation of batch fryers are relatively straightforward, making them easier to maintain and clean.

Cost-Effectiveness: For smaller production volumes, batch fryers may be more cost-effective to install and operate than continuous fryers.

Limitations of Batch Fryer:

Time-Consuming: The batch frying process takes more time compared to continuous frying, as each batch needs individual attention.

Inconsistent Results: Batch frying can lead to slight variations in product quality between batches, depending on factors like oil temperature and frying time adjustments.

Continuous Fryer

Continuous fryers, on the other hand, are designed for high-volume industrial frying operations. These fryers provide a continuous flow of food products through the frying process, ensuring a consistent output and improved efficiency. In a continuous fryer system, the food items are fed into the fryer through a conveyor belt or a similar mechanism, and they travel through the hot oil until fully cooked before being automatically discharged.

Advantages of Continuous Fryer:

High Productivity: Continuous fryers can handle a continuous flow of food products, resulting in higher production rates compared to batch fryers.

Consistency: The continuous flow of products ensures uniform frying times and temperatures, leading to consistent product quality.

Energy Efficiency: Since continuous fryers maintain a constant oil temperature, they can be more energy-efficient than batch fryers.

Limitations of Continuous Fryer:

Limited Product Variety: Continuous fryers are more suitable for processing a single type of product or a narrow range of similar products due to continuous operation.

Initial Investment: Continuous fryers typically require a larger initial investment than batch fryers, making them more suitable for large-scale food production facilities.

In summary, the choice between a batch fryer and a continuous fryer depends on various factors, including the scale of production, product variety, and budget constraints. Food businesses must carefully assess their frying needs and goals to select the most appropriate fryer system that aligns with their production requirements and resources. Both batch fryers and continuous fryers play critical roles in the food industry, offering effective frying solutions for a wide range of products.

Batch Fryer

A batch fryer is a traditional frying system where food products are fried in specific batches. The process involves immersing the food items into hot oil until they reach the desired level of crispiness and color. After each batch is fried, the food is removed, and a new batch is added. This method is commonly used in smaller-scale operations, such as restaurants, food trucks, and some small to medium-sized food production facilities.

Advantages of Batch Fryer:

Versatility: Batch fryers can handle a wide variety of products, as different items can be fried in separate batches without flavor mixing.

Simplicity: The setup and operation of batch fryers are relatively straightforward, making them easier to maintain and clean.

Cost-Effectiveness: For smaller production volumes, batch fryers may be more cost-effective to install and operate than continuous fryers.

Limitations of Batch Fryer:

Time-Consuming: The batch frying process takes more time compared to continuous frying, as each batch needs individual attention.

Inconsistent Results: Batch frying can lead to slight variations in product quality between batches, depending on factors like oil temperature and frying time adjustments.

Continuous Fryer

Continuous fryers, on the other hand, are designed for high-volume industrial frying operations. These fryers provide a continuous flow of food products through the frying process, ensuring a consistent output and improved efficiency. In a continuous fryer system, the food items are fed into the fryer through a conveyor belt or a similar mechanism, and they travel through the hot oil until fully cooked before being automatically discharged.

Advantages of Continuous Fryer:

High Productivity: Continuous fryers can handle a continuous flow of food products, resulting in higher production rates compared to batch fryers.

Consistency: The continuous flow of products ensures uniform frying times and temperatures, leading to consistent product quality.

Energy Efficiency: Since continuous fryers maintain a constant oil temperature, they can be more energy-efficient than batch fryers.

Limitations of Continuous Fryer:

Limited Product Variety: Continuous fryers are more suitable for processing a single type of product or a narrow range of similar products due to continuous operation.

Initial Investment: Continuous fryers typically require a larger initial investment than batch fryers, making them more suitable for large-scale food production facilities.

In summary, the choice between a batch fryer and a continuous fryer depends on various factors, including the scale of production, product variety, and budget constraints. Food businesses must carefully assess their frying needs and goals to select the most appropriate fryer system that aligns with their production requirements and resources. Both batch fryers and continuous fryers play critical roles in the food industry, offering effective frying solutions for a wide range of products.

Tel:0086-15515573212

Tel:0086-15515573212  E-mail:sherry@gelgoog.com

E-mail:sherry@gelgoog.com