How much do you know about French fries?

Apr 30, 2019 | Nick

83

83

83

83

As early as 1680, the Belgian began making French fries. During the first World War, American soldiers had this French fries in Belgium. And feel particularly delicious, so as to become popular. But they call it "French", It was because the common language of the Belgian army was French,so they thought it was "French fries".

In modern,Frozen French Fries because of it's fast, simple, and delicious has become one of the most popular foods. Both McDonald's and KFC's French fries are frozen French fries that need to be fried again before eating. As more nutrients are retained in production, the frozen fries have a more appealing appearance and taste.Low-oil, high-quality frozen fries with golden yellow and fresh, tender crispy skin. Attractive colors depend primarily on blanching time and frying time, while cooling time and frying temperature have a large effect on oil content and moisture content.

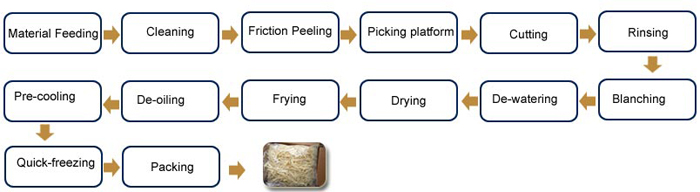

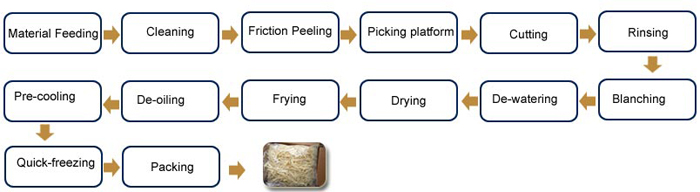

Frozen French Fries Process Flow:

Frozen French Fries Processing Machinery:

How does Frozen French Fries Production Line work?

If you are interested in processing frozen french fries to sell and want to know more about the frozen french fries processing machinery,welcome to contact to me by email or phone.

Email:emily@machinehall.com

Phone/Whatsapp:+8615538388305

Website:http://www.fryingm.com/products/french-fries-production-line.html

In modern,Frozen French Fries because of it's fast, simple, and delicious has become one of the most popular foods. Both McDonald's and KFC's French fries are frozen French fries that need to be fried again before eating. As more nutrients are retained in production, the frozen fries have a more appealing appearance and taste.Low-oil, high-quality frozen fries with golden yellow and fresh, tender crispy skin. Attractive colors depend primarily on blanching time and frying time, while cooling time and frying temperature have a large effect on oil content and moisture content.

Frozen French Fries Process Flow:

Frozen French Fries Processing Machinery:

- Potato Washing and Peeling Machine: By Elevator, the potato will come into the Pre-washing Machine, by brush roller and water spraying to remove the mud on the surface of potato. After washing, the potato will come into the emery peeling machine to remove the peel.

- French Fries Cutting Machine:The machine has the characteristics of good cutting quality, high cutting efficiency, easy operation and low energy consumption.The cutting size of french fries can be customized according to the needs of customers.

- French fries Blanching Machine:Remove starch from potato, inhibit active enzyme activity and protect color.

- Dewatering Machine:It's good for less frying time.

- Continuous Frying Machine:Deep-fry to color, and optimize the taste and taste.

- Centrifugal Deoiling machine:Remove excess oil from the surface.

- Packing Machine:Packing frozen french fries to store and seel.

How does Frozen French Fries Production Line work?

If you are interested in processing frozen french fries to sell and want to know more about the frozen french fries processing machinery,welcome to contact to me by email or phone.

Email:emily@machinehall.com

Phone/Whatsapp:+8615538388305

Website:http://www.fryingm.com/products/french-fries-production-line.html

Tel:0086-15515573212

Tel:0086-15515573212  E-mail:sherry@gelgoog.com

E-mail:sherry@gelgoog.com