What Is The Production Cycle of Potato Chips?

Oct 12, 2023 | Emily

117

117

117

117

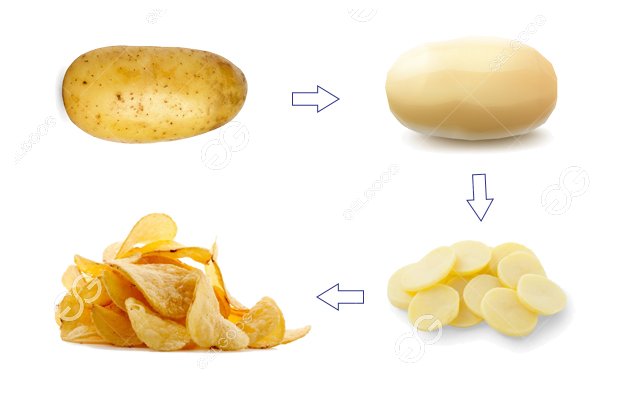

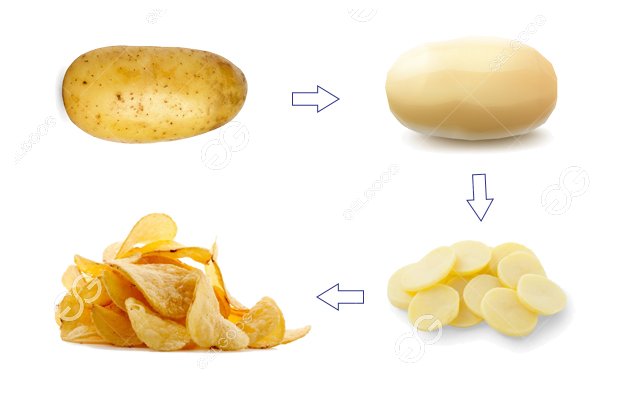

Potato chips, a beloved snack enjoyed by people worldwide, undergo a fascinating production cycle in a factory before they find their way into the hands of consumers. From humble potatoes to the crispy, flavorful chips we love. But what is the production cycle of potato chips?

Potato selection and cleaning

The journey of a potato chip begins with the careful selection of the raw ingredient: Potatoes. Potatoes are sorted to ensure quality, and any defective or damaged ones are removed. After sorting, the selected potatoes are thoroughly washed and cleaned to remove dirt and debris.

Peeling and slicing

Once cleaned, the potatoes move on to the peeling and slicing stage. In industrial potato chip production, large machines perform the task of peeling and slicing the potatoes with great precision. The thickness of the slices can vary to produce different types of chips, from thin and crispy to thicker, kettle-cooked chips.

Pre-cooking

The potato slices then go through a process called pre-cooking. This step involves blanching the slices in hot water or steam to partially cook them. Pre-cooking serves multiple purposes, including softening the potatoes, removing excess sugars, and preparing the slices for the next stages of production.

Frying

In a continuous fryer, they are submerged in hot oil. This is the critical stage where the potato slices turn into crispy chips. The temperature and duration of frying are closely monitored to achieve the desired texture and color.

Oil removal and cooling

After frying, the chips emerge from the oil bath and go through a conveyor system that helps remove excess oil. This step is crucial to ensure the chips are not overly greasy. Following oil removal, the chips are rapidly cooled using air to set their crispness.

Quality control

Quality control is a constant process throughout the production cycle. Factory workers inspect the chips for any imperfections, ensuring only high-quality products make it to the packaging phase. Any defective chips are removed.

Packaging

Once the chips pass quality control, they are ready for packaging. Packaging methods can vary from simple foil-lined bags to more elaborate designs, depending on the brand and type of chips. A filling machine accurately portions the chips into each bag.

Distribution

With the bags of potato chips sealed and ready, they are prepared for distribution to various retailers and markets. The chips may be shipped in bulk to distribution centers or directly to stores.

The production cycle of potato chips in a factory is a meticulous and well-orchestrated process. From the selection of high-quality potatoes to the final packaging, each step plays a crucial role in creating the crispy, flavorful snacks we all love. If you have any demand of potato chips production line, contact us by following ways:

Email: Sherry@machinehall.com

Phone/whatsapp: 0086-15515573212

Potato selection and cleaning

The journey of a potato chip begins with the careful selection of the raw ingredient: Potatoes. Potatoes are sorted to ensure quality, and any defective or damaged ones are removed. After sorting, the selected potatoes are thoroughly washed and cleaned to remove dirt and debris.

Peeling and slicing

Once cleaned, the potatoes move on to the peeling and slicing stage. In industrial potato chip production, large machines perform the task of peeling and slicing the potatoes with great precision. The thickness of the slices can vary to produce different types of chips, from thin and crispy to thicker, kettle-cooked chips.

Pre-cooking

The potato slices then go through a process called pre-cooking. This step involves blanching the slices in hot water or steam to partially cook them. Pre-cooking serves multiple purposes, including softening the potatoes, removing excess sugars, and preparing the slices for the next stages of production.

Frying

In a continuous fryer, they are submerged in hot oil. This is the critical stage where the potato slices turn into crispy chips. The temperature and duration of frying are closely monitored to achieve the desired texture and color.

Oil removal and cooling

After frying, the chips emerge from the oil bath and go through a conveyor system that helps remove excess oil. This step is crucial to ensure the chips are not overly greasy. Following oil removal, the chips are rapidly cooled using air to set their crispness.

Quality control

Quality control is a constant process throughout the production cycle. Factory workers inspect the chips for any imperfections, ensuring only high-quality products make it to the packaging phase. Any defective chips are removed.

Packaging

Once the chips pass quality control, they are ready for packaging. Packaging methods can vary from simple foil-lined bags to more elaborate designs, depending on the brand and type of chips. A filling machine accurately portions the chips into each bag.

Distribution

With the bags of potato chips sealed and ready, they are prepared for distribution to various retailers and markets. The chips may be shipped in bulk to distribution centers or directly to stores.

The production cycle of potato chips in a factory is a meticulous and well-orchestrated process. From the selection of high-quality potatoes to the final packaging, each step plays a crucial role in creating the crispy, flavorful snacks we all love. If you have any demand of potato chips production line, contact us by following ways:

Email: Sherry@machinehall.com

Phone/whatsapp: 0086-15515573212

Tel:0086-15515573212

Tel:0086-15515573212  E-mail:sherry@gelgoog.com

E-mail:sherry@gelgoog.com