Features

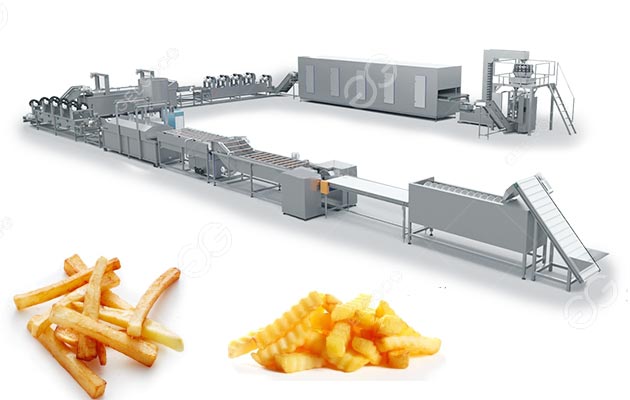

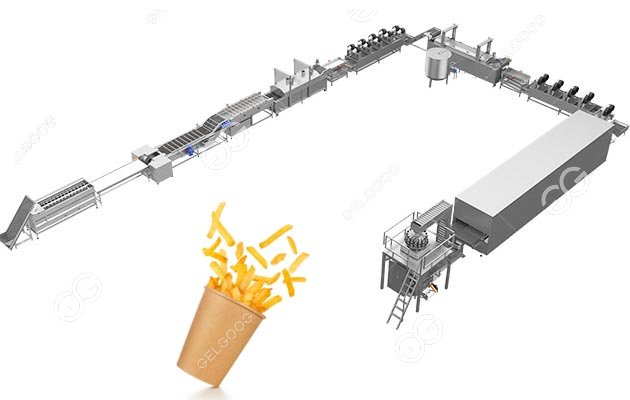

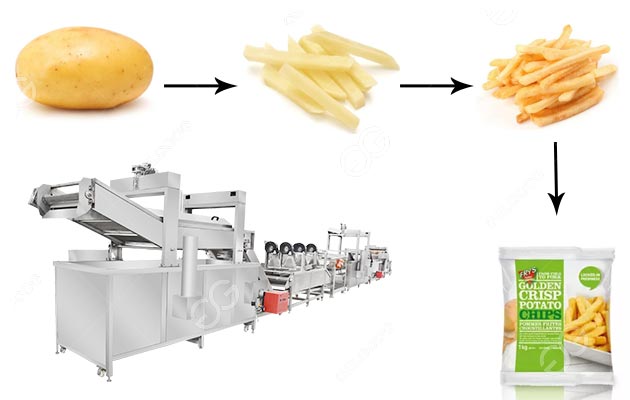

Introduction of Commercial French Fries Production Line:

This hot selling french fries making line is designed for small and medium chip makers. As professional french fries production line manufactuers, we offer three different models of 150 kg/h, 300 kg/h, 500 kg/h ,1000kg/h and more other capacity for you. This commercial french fries production line is cheap and efficient, and is the best choice for processing french fries.

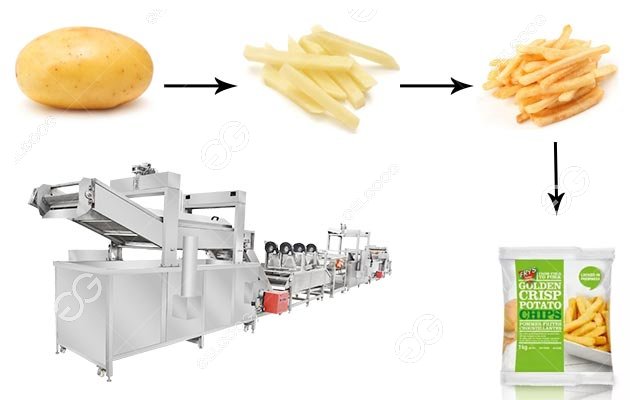

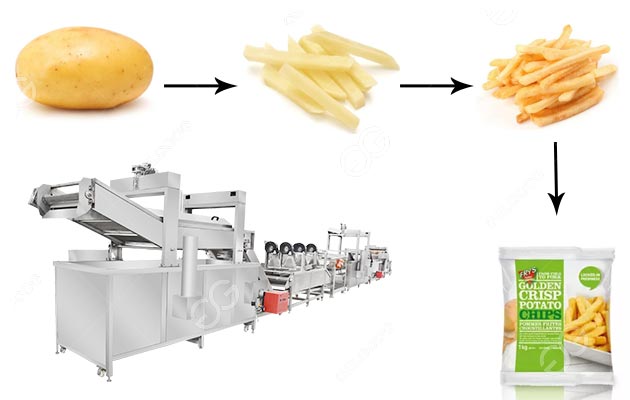

Working Flow of Commercial French Fries Making Machine:

Lifting and feeding - cleaning peeling - selecting - feeding - cutting into strips - rinsing - blanching for protecting color - removing excesss water - continuous frying - removing surface oil from fried french fries -flavoring - packaging

Introduction of the main machine for Frozen French Fries Making Machine:

Features of Automatic Frozen French Fries Production Line:

Advantages of Frozen French Fries Production Line:

1, Stainless steel, easy to operate, high productivity and high efficiency.

2, Made of stainless steel, advanced technology, long service life.

3, The machines meet stringent international quality standards.

4, Very reasonable price for the equipment.

How does our French Fries Production Line work?

This hot selling french fries making line is designed for small and medium chip makers. As professional french fries production line manufactuers, we offer three different models of 150 kg/h, 300 kg/h, 500 kg/h ,1000kg/h and more other capacity for you. This commercial french fries production line is cheap and efficient, and is the best choice for processing french fries.

Working Flow of Commercial French Fries Making Machine:

Lifting and feeding - cleaning peeling - selecting - feeding - cutting into strips - rinsing - blanching for protecting color - removing excesss water - continuous frying - removing surface oil from fried french fries -flavoring - packaging

Introduction of the main machine for Frozen French Fries Making Machine:

- French Fries Cutting Machine:This machine adopts vertical knife simulates manual cutting principle, the processed surface is smooth; the shape is regular; the cutting-off vegetables is fresh and its organization is in nice condition with the high quality.

- Blanching machine:the activity of the enzymes in the fries is stopped and the fries therefore maintain a fresh color and a unique taste. Improve cell flexibility, which will help water evaporation. Prepare for the next frying.

- French Fries Frying Machine:oil-water separation system is used. This extends the life of the oil. This kind of fryer is a continuous work, automatic feeding and automatic unloading, the conveyor unloads the material through the conveyor.

- Deoiling machine:adopts anti-impact system and adopts centrifugal principle, electromagnetic brake, digital automatic control, stainless steel and other equipment. Food will not be thrown out during deoiling process.

- French Fries Seasoning Machine:The seasoning machine can realize automatic mixing materials, so also called it the drum food seasoning machine, easy to use.

Features of Automatic Frozen French Fries Production Line:

1.Highly automated, which can save labor and reduce the cost of machine operation.

2. All machines are made of stainless steel 304.

3. Advanced technology guarantees lower energy cost and lower labor cost.

4. The installation project can be customized according to customers' factory.

5.Different production capacity for selection, from 100-1000 kg/h.

Advantages of Frozen French Fries Production Line:

1, Stainless steel, easy to operate, high productivity and high efficiency.

2, Made of stainless steel, advanced technology, long service life.

3, The machines meet stringent international quality standards.

4, Very reasonable price for the equipment.

How does our French Fries Production Line work?

Technial Data

| Item | Parameter |

| 1, Elevator |

0.75kw/380v/50Hz 2000*800*2000mm |

| 2, Cleaning and Peeling Machine |

4.75kw/380v/50Hz 1800*900*1500mm |

| 3, Sorting Conveyor |

0.75kw/380v/50Hz 3000*900*900mm |

| 4, Potato Chips Cutting Machine |

1.5kw/380v/50Hz 950*800*950mm |

| 5, Rinshing Machine |

5kw/380v/50Hz 3500*1600*900mm |

| 6, Blanching Machine |

70kw/380v/50Hz 3500*1600*950mm |

| 7,Vibrating and Water Removing Machine |

1.5kw/380v/50Hz 1500*1000*1300mm |

| 8,Sorting Conveyor |

0.75kw/ 380V/50Hz 4000*800*1000mm |

| 9, Air Cooling and water removing machine |

15kw/380v/50Hz 4000*1200*1400mm |

| 10,Elevator |

0.75kw/380v/50hz 2500*800*1300mm |

| 11, Electric Continuous Fryer Machine |

120kw/380v/50Hz 4000*1200*2600mm |

| 12, Vibrating and Oil Removing Machine |

1.5kw/380v/50Hz 1500*1000*1300mm |

| 13,Air Drying Machine |

8kw/380v/50Hz 4000*1200*1600mm |

| 14,Elevator |

0.75kw/380v/50Hz 2400*800*2200mm |

| 15,Flavoring Machine |

50kw/380v/50hz 2500*900*1500mm |

Tel:0086-15515573212

Tel:0086-15515573212  E-mail:sherry@gelgoog.com

E-mail:sherry@gelgoog.com