Features

The onion fried in the Onion frying machine has a crispy texture and is a very popular snack. The automatic frying machine for frying onions(Shallots) provided by our company is mainly divided into two types: continuous frying machine and Round basket frying machine. In addition, our company also provides professional onion frying production line.

Continuous Onion Frying Machine

The onion fry machine adopts a double mesh belt design, and the speed of the mesh belt is adjustable during the conveying process. The fuel injection pipe can be designed at the feed port at the same time with a high-pressure air stirring device, which can effectively prevent the material from sticking. The frying output of this fryer is large and can meet the standards of mass production.

Round Basket Shallots Frying Machine

This shallots frying machine adopts the design of a round frying basket, which can automatically stir during frying to save manpower. The diameter of the fryer can be customized according to requirements and can be used with the production line.

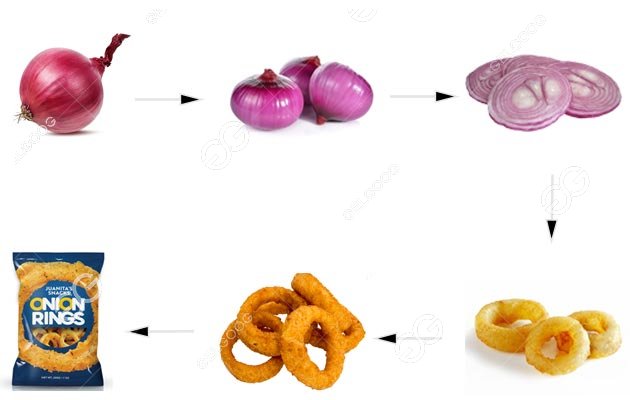

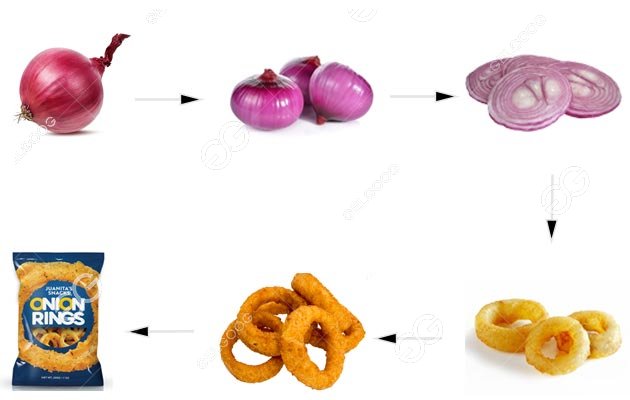

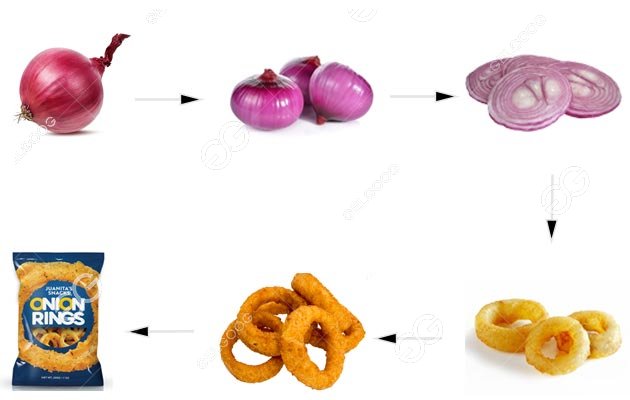

Fried Onion/Shallots Solution

In addition to the above two types of frying machines, we also provide solutions for frying onions(shallots). Mainly include cutting the root, peeling, cutting, cleaning, frying, degreasing, seasoning, packaging, quick freezing and so on. As a supplier of professional onion production line, we are committed to solving the actual needs of customers, and customization is welcome.

Scope Of Application

The onion frying machine provided by our company makes the product quality stable, uniform in color, fragrance and taste, and is suitable for a variety of materials. Mainly used in: French fries, potato chips, plantain chips, peanuts, tofu, pork skin, sweet potato chips, etc.

Continuous Onion Frying Machine

The onion fry machine adopts a double mesh belt design, and the speed of the mesh belt is adjustable during the conveying process. The fuel injection pipe can be designed at the feed port at the same time with a high-pressure air stirring device, which can effectively prevent the material from sticking. The frying output of this fryer is large and can meet the standards of mass production.

- Using high-quality stainless steel materials to meet food safety standards.

- The upper and lower mesh belts and hood of the fryer can be lifted for easy cleaning.

- Optional heating method (electric heating, gas heating)

- Automatic feeding and discharging.

- High degree of automation, the output per hour can be customized according to customer needs

- The frying temperature and time can be adjusted.

- Integrate filtration system, temperature control system, frying system and heat circulation system

Round Basket Shallots Frying Machine

This shallots frying machine adopts the design of a round frying basket, which can automatically stir during frying to save manpower. The diameter of the fryer can be customized according to requirements and can be used with the production line.

- With its own stirring function to ensure even frying

- After frying, the material can be lifted and discharged.

- And multi-purpose, can deep-fry different materials.

- The oil has a long service life, and there is no need to change the oil frequently.

- Exquisite workmanship, safe and reliable, sturdy and durable.

Fried Onion/Shallots Solution

In addition to the above two types of frying machines, we also provide solutions for frying onions(shallots). Mainly include cutting the root, peeling, cutting, cleaning, frying, degreasing, seasoning, packaging, quick freezing and so on. As a supplier of professional onion production line, we are committed to solving the actual needs of customers, and customization is welcome.

Scope Of Application

The onion frying machine provided by our company makes the product quality stable, uniform in color, fragrance and taste, and is suitable for a variety of materials. Mainly used in: French fries, potato chips, plantain chips, peanuts, tofu, pork skin, sweet potato chips, etc.

Technial Data

| Model |

Belt width (mm) |

oil pump power (kw) |

lifting power (kw) |

heating power |

Dimension (mm) |

| GGLZG3500A | 800 | 1.5 | 0.55 | 20Wkcal | 3700*1900*2400 |

| GGLZG5000A | 800 | 1.5 | 0.55*2 | 30Wkcal | 5200*1900*2400 |

| GGLZG6500A | 800 | 1.5 | 0.75*2 | 20Wkcal*2 | 6700*1900*2400 |

| GGLZG8000A | 800 | 2.2 | 0.75*2 | 30Wkcal*2 | 8200*1900*2400 |

| GGLZE3500A | 800 | 1.5 | 0.55 | 90KW | 3700*1600*2200 |

| GGLZE5000A | 800 | 1.5 | 0.55*2 | 120kw | 5200*1600*2200 |

| GGLZE6500A | 800 | 1.5 | 0.75*2 | 190kw | 6700*1600*2200 |

| GGLZE8000A | 800 | 2.2 | 0.75*2 | 255kw | 8200*1600*220 |

Tel:0086-15515573212

Tel:0086-15515573212  E-mail:sherry@gelgoog.com

E-mail:sherry@gelgoog.com