Features

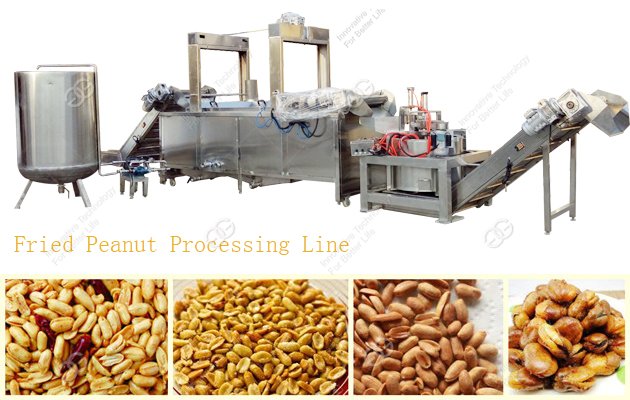

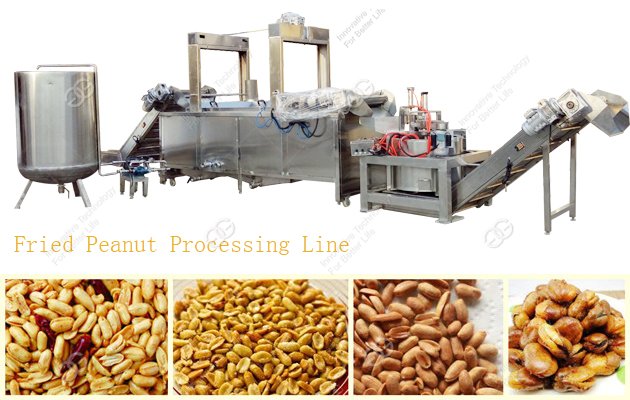

The peanut processing line consists of seven sets of machines, high production efficiency, easy to operate. This fried peanut processing line can realize automatic working, high working efficiency and automatic discharging. Can widely used for frying fava beans, green beans, peanuts and other nuts leisure food.We also supply dry type peanut frying production line.

Working Process of Fried Peanut Processing Machine:

Sorting conveyor to sort the unqualified peanut---Soaking Peanut---Wet peeling machine to remove the skin of peanut---Peanut frying machine---Deoiling machine to remove excess oil from the surface of fried peanut---Air drying machine---Seasoning machine--Packing

Introduction of Main Machine in Fried Peanut Processing Line:

For Wet Peeling Machine: Before peeling, the peanut need to be soak by hot water. The machine peels the peanuts clean and does not damage themWhen this machine working, it needs water all the time. Should connect the water pipe firstly, then turn on the machine.

For Peanut Fryer Machine: The machine uses oil-water mixing and frying technology to save oil in the production process. The frying time and temperature can be adjusted by the temperature control system to ensure that the peanuts are fried evenly and the quality of the frying is high.

For Deoiling Machine: The machine is new developed and with high technology. It can feed and discharge automatically. Made of stainless steel,the production process is safer and more hygienic. For this machine, it is also with one bucket, and the size of hole on the bucket also can be customized according to material size.,to ensure better deoiling effect.

For Seasoning machine: The machine can mix seasonings with peanuts evenly, unique octagonal design, seasoning without dead ends.

How does our machine work?

Working Process of Fried Peanut Processing Machine:

Sorting conveyor to sort the unqualified peanut---Soaking Peanut---Wet peeling machine to remove the skin of peanut---Peanut frying machine---Deoiling machine to remove excess oil from the surface of fried peanut---Air drying machine---Seasoning machine--Packing

Introduction of Main Machine in Fried Peanut Processing Line:

For Wet Peeling Machine: Before peeling, the peanut need to be soak by hot water. The machine peels the peanuts clean and does not damage themWhen this machine working, it needs water all the time. Should connect the water pipe firstly, then turn on the machine.

For Peanut Fryer Machine: The machine uses oil-water mixing and frying technology to save oil in the production process. The frying time and temperature can be adjusted by the temperature control system to ensure that the peanuts are fried evenly and the quality of the frying is high.

For Deoiling Machine: The machine is new developed and with high technology. It can feed and discharge automatically. Made of stainless steel,the production process is safer and more hygienic. For this machine, it is also with one bucket, and the size of hole on the bucket also can be customized according to material size.,to ensure better deoiling effect.

For Seasoning machine: The machine can mix seasonings with peanuts evenly, unique octagonal design, seasoning without dead ends.

How does our machine work?

Technial Data

| Wet Type Peanut Frying Production Line | |

|

Item |

Parameter |

| Sorting Conveyor |

Power:2.25KW Dimension:3000*1000*900mm |

|

Peanut Wet Peeling Machine |

Dimension1100*550*950mm Power:1.5KW |

|

Fryer Machine |

Dimension: 1700*1800*1600mm Power: 48kw |

|

De-oiling Machine |

Dimension: 1200*1100*1400mm Power: 1.5kw |

| Elevator |

Dimension: 1800*1200*1500mm Power:0.75kw |

|

Air-Drying Machine |

Dimension: 3000*1000*1400mm Power: 8.6kw |

|

Seasoning Machine |

Dimension: 1000*800*1300mm Power: 1.1kw |

Tel:0086-155-383-88305

Tel:0086-155-383-88305  E-mail:Emily@machinehall.com

E-mail:Emily@machinehall.com